Wipro: Surface Quality Inspection for a Manufacturing Plant

Industry:

Manufacturing

Use Case:

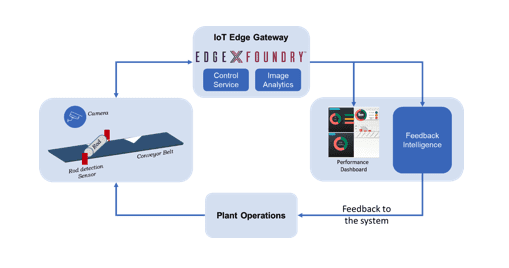

Using EdgeX Foundry to acquire and analyse sensor data to automate surface quality inspection for a manufacturing plant that produces Piston Rods used in different applications like Utility, Mining, Construction and Earth Moving.

Written by LF Edge members from Wipro. For more information about Wipro, visit their website.

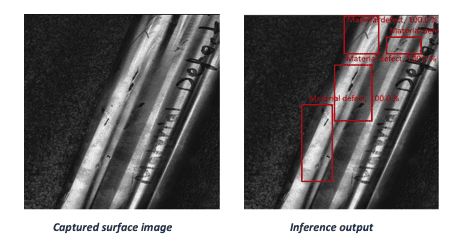

In a manufacturing plant, the production of piston rods goes through multiple stages like induction hardening, friction welding, threading & polishing. Each of these stages has a quality checkpoint to detect defects in the early stages and to ensure that the rods produced are in line with design specifications & function properly. After it goes through a rigorous multi-stage process, it reaches the final station where surface-level quality inspection happens. At this stage, the quality inspection happens manually, requiring highly skilled & experienced human inspectors to look for different types of defects like scratches, material defects & handling defects on the surface of rods. Based on the final quality inspection results, it goes either to the packaging & shipment area or to the rework or scrap area.

Quality check at every stage is extremely critical to prevent quality problems down the line leading to recalls & reputational damages. The problem with manual inspections – they are costly, time-consuming, and heavily dependent on human intelligence & judgment. “Automated surface quality inspection” is an image analytics solution based on Artificial Intelligence / Machine Learning that helps overcome these challenges. The solution identifies and classifies defects based on image analytics to enable quality assessment and provides real-time visibility to Key Performance Indicators through dashboards to monitor the manufacturing plant performance.

EdgeX architectural tenets, production-grade readily available edge software stack, visibility of long-term support with a bi-annual release roadmap, and user-friendly licensing for commercial deployments made us adopt EdgeX as the base edge software stack.

The readily available edge IoT gateway functionalities helped us focus more on building business application-specific components than the core software stack needed for an edge gateway. This helped us in the rapid development of proof of concept for the use case we envisioned.

Key components of the solution include:

- Edge Gateway hardware, Industrial grade camera & a sensor to detect piston rods placed in the final quality inspection station

- Edge Software components:

- Gateway powered by EdgeX's open edge software stack with enhancements to support the use case

- Deep machine learning model trained with previously analyzed & classified defects

- Intel’s OpenVino toolkit for maximizing video inference performance on the edge gateway

- EdgeX Device Service Layer enhancements to enable missing southbound connectivity

- Automated decision-making in the edge by leveraging EdgeX provided local data analytics capability

- EdgeX AppSDK customizations to connect to business applications hosted on the cloud

- Industrial Automation software platform with a performance dashboard to define, create and monitor Key Performance Indicators

Once the rod reaches the inspection station, the gateway triggers the camera to take surface pictures. The image captured is fed into the inference engine running on the gateway, which looks for the presence of different types of surface defects. The inference output is fed into the business application hosted on the cloud to provide actionable insights with rich visual aids.

The analysis of historical edge data for a similar pattern of defects, correlating data from OT systems with inference output for a given time period, and providing feedback to OT systems for potential corrective actions are possible future enhancements.

Benefits:

- Reduced inspection cost: Automated quality inspections, reduced need for manual inspection

- Centralized management: Real-time visibility of plant operations from remote locations

- Consistent performance: Less dependency on human judgment, which varies from one person to another

- Reduced inspection time: Consistent & reliable results in a much shorter time

- Learning on the go: Continuous retraining of deep learning models makes automated inspections accurate & closer to reality

- Available 24 x 7

If you have questions or would like more information about this industrial automation software use case for the manufacturing industry of LF Edge member Wipro, please email naga.shanmugam@wipro.com.